HISTORY

We started as “Wilhelm Settele Design-office” in 1987, in Fuessen, in the picturesque Allgau region of Bavaria. Our initial focus was Product and Process development for Medical-Instruments. Through our sophisticated designs in this field, we gained a reputation as provider of clever, high precision solutions for sensitive applications.

For example, we developed the complete plug-in Connector system for the smallest (at that time), mobile Blood -pressure measuring unit and for Boehringer, a pain free Lancet for drawing blood for glucose test by diabetics.

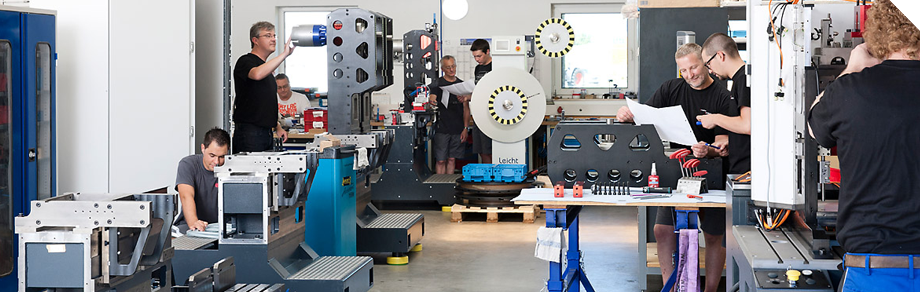

From the resourceful, “creative” design office, with limited financial means, grew creative automation, gradually, to today’s expanding success. Due to the expanding from various industries we have become a valued service and product provider for the Automotive, Appliance, Electronic, Instrument and Horology Industries.

Recalling the starting phase, Willy Settele, the founder said:

“All, who were with me through these times, all who enabled me to learn and grow, all who supported us, as customers or suppliers, have my deepest gratitude.”

EXCEPTIONAL SOLUTIONS:

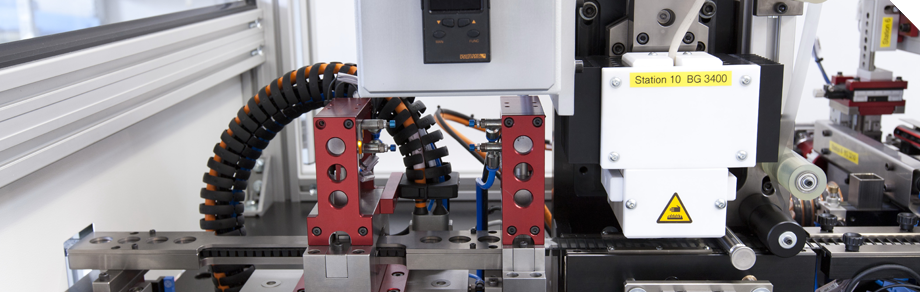

- We build automated systems and individual insertion units for insulation displacement (IDC) terminals

- We provide final assembly systems for the integration of led-frames and injection molding units for hybrid components

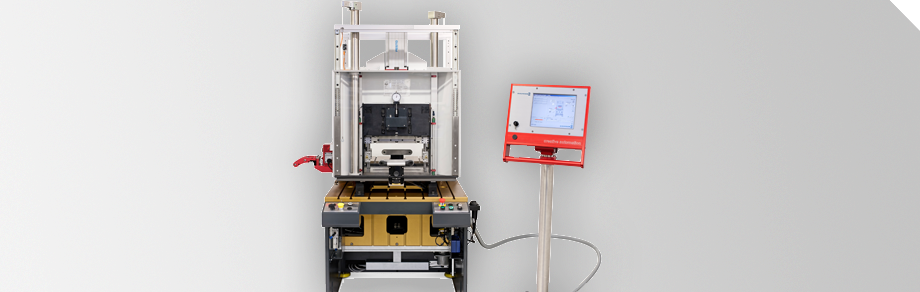

- We developed the ProX 100 as modular processing unit for the engineering of prototypes and production

- A partnership with BRUDERER company for the sales and marketing of our systems in Switzerland and Vorarlberg (Western-Austria)

After 23 years as a sole proprietorship, a new chapter in the company’s development began in 2010 with the entry of ZETKA with a 70% stake.

After creative automation bought back the shares held by ZETKA on November 30, 2015, new powerful partners came on board. Here, creative automation acts as a competence center for stamping and forming technology. This enables further investments in the development and marketing of our machines and systems.

Currently, the core staff consists of 18 employees. In addition, up to 40 freelancers and cooperation partners are constantly working on our projects.